Let’s Have A Block Party! Historic Rock-Face Block in America

I wrote recently about my married children buying a historic house. I geek out over many things, and their tackling this old dwelling has provided the fodder for many hours of geekery on the part of their father. Early on, I was trying to date the house that they bought. The city assessor’s online records said it was 1900, but I had my doubts. Many of us know that 1900 was often a default date for garbage computer data (remember – garbage in, garbage out). But the other thing that caused me doubt was the use of an old style of concrete block for the foundation and porch.

I had seen this stuff used on old houses all my life. I wondered what it was called, and learned that it has a few names. It us usually called “rock face block”, but is also known as “rusticated block”. And the stuff turns out to have an interesting history.

Concrete, it seems, is a relatively modern building material. Yes, the ancient Romans used it (and in a formula that has been slow to give up its secrets) but it was not used again in the English-speaking world until the 1850’s in England and the 1880’s in the U.S. The thing that pushed it into the big time was the increased availability of a key ingredient – Portland cement, which was a lime-based cement named for a resemblance to stone quarried on the Isle of Portland in England.

The stuff’s relatively plentiful supply came just as a building boom was taking off in America. There was only so much quarried stone available for construction, and only so many men available to cut it and transport it to sites far from the quarries. Although concrete (a mixture of rock/sand aggregate and cement) started to see some use, it did not become widespread until Harmon S. Palmer acted on an idea.

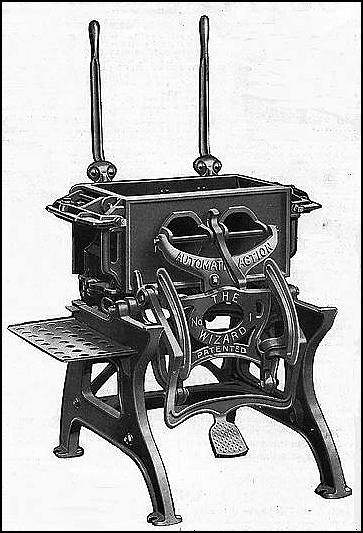

Palmer knew that concrete blocks roughly the size of quarried stones could be stronger than brick and also less expensive than genuine stone or even brick, depending on the distance necessary for transport from the kilns. In 1900, Palmer patented a block-making machine. That machine, designed to make concrete blocks on the building site, came along just as America’s building boom was heading for new heights.

Of course, Palmer started selling the machines and was soon joined by other companies – including America’s first nationwide building supply company, Sears, Roebuck & Co. These “Palmer machines” were soon found from coast to coast so that masons, farmers or even untrained laborers were able to churn out blocks one after another after another. Sears began to include rock-faced block into many of its popular homebuilding kits, most likely by offering a block-making machine to go with the plans and materials.

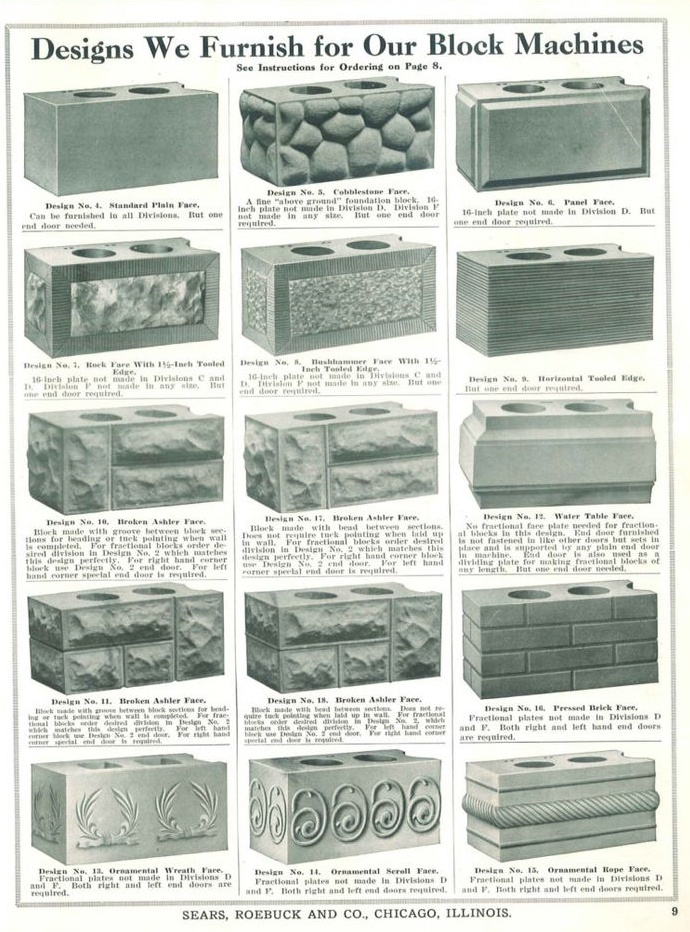

Although the version here was the most commonly seen by far, these machines offered the ability to make block with many different face patterns, as shown by the Sears ad, above. With these many decorative options, concrete block had become an almost magic building material that could mimic all kinds of other materials.

By the 1920’s, the stuff was everywhere. In addition to foundations and porches, it was used for entire homes, as well as for garages and commercial buildings where speed of construction, durability and low cost were prized. A drive through any area built from shortly after 1900 to perhaps 1930 will yield many structures that used these blocks and are still standing.

It was only in the 1930’s when the material began to fall out of favor, and it had mostly vanished from the building trades by 1940. Part of the change was that commercial blockmaking operations could, by then, produce smooth-faced blocks in vast numbers, negating the cost advantage of making them one or two at a time on site with a Palmer machine. And the mass-produced blocks undoubtedly had more even quality control, not being subject to poorly combined ingredients. Then after WWII broke out and scrap metal became a precious commodity, many old Palmer machines were melted down for the war effort, taking them permanently out of circulation.

There are some modern companies that have taken to supplying new-production rock-face block so that historic structures may be repaired or restored using authentic materials. However, many of the old houses and other structures continue to sit on solid foundations made by the use of Palmer machines over a century ago.

To circle back to my original project, it was clear that this house almost had to have been built after 1901 because of the extensive used of rock-face block for the foundation and porch. For those who like their mysteries to come with a solution, other sources eventually convinced me that 1907 was likely the year of actual construction in what were then the suburbs of Indianapolis.

I had struggled to come up with a topic for this week – I had several ideas floating around, but nothing concrete. But as is now apparent, my childrens’ new home and my geekery over its fascinating history provided the cure for a bad case of (wait for it) writer’s block.

Very interesting entry, and this stuff is all over Milwaukee in pre depression era residential buildings, mostly for the foundations. I always thought they were cut that way, so this is an eye opener!

LikeLiked by 1 person

Like you, I had noticed these things forever. But I had known nothing about them until they became a rabbit hole that became a slight detour from my main rabbit hole of trying to date this particular house. It is also interesting as a trend that completely dominated construction for 25+ years and then disappeared almost instantly.

LikeLike

That’s the beauty of concrete…you can make blocks with it and hold them together with mortar made from more of it. In turn, you can go to the store to buy the ancillary components of the house and use concrete streets to get there.

While I have seen this more for patios, sidewalks, and driveways, there are currently ways to mimic this (and countless other designs) with stencils and stains. You can have what looks like a brick patio that is simply concrete that was dumped from the ready-mix truck.

The wonderful thing about the blocks you describe is they are undoubtedly maintenance free. Those last two words get some of us really excited.

LikeLiked by 1 person

With as many things as can deteriorate in a 100+ year old house (ask me about cast iron drain pipe some time) it is a delight that one component is literally as good as new. Other than the need to paint the stuff (due to the decor choice of some long-ago owner) it needs nothing and still looks great.

I had always assumed that these blocks were, like all other building materials, hauled to the site from elsewhere. I had no idea they were made right there for that particular job. Maybe we should keep an eye out for one of these old machines so that after the apocalypse comes, we can become essential when something needs to be built. 🙂

LikeLiked by 1 person

This is interesting. It looks like a lot of work for a labor-saving device, lol.

LikeLiked by 1 person

Haha, true! But I guess it’s still easier than cutting stone.

LikeLiked by 1 person

Wow, that was super interesting. There’s a bit of that cast block in our town but I too had assumed they were pre-made and not by such a laborious process. Great video too, perhaps all 1900’s construction was accompanied by opera music, just as WW1 was fought in silence and black & white.

LikeLiked by 2 people

The opera music thing could have been possible. The year my kids’ house was probably built (1907) Enrico Caruso had the number 1 seller phonograph record.

I have never really looked into it, but I think the modern cinder block is made of something else than the traditional concrete mix used in these. I am kind of amazed that the concrete doesn’t stick to the old machines as they made the blocks. I keep wondering if they needed the 1905 equivalent of cooking spray on a waffle iron to make the blocks come out as clean as they did. But this question probably just shows how little I know about working with concrete.

LikeLike

Interesting topic. I’ve seen houses and buildings made of that kind of cement block but never knew the history. Better than “Permastone” which is really tacky-looking stuff (most of the time!)

Now if you really want to “geek out” on something, how about this? The Alonzo C. Rand House, 525 7th St. S., Minneapolis; built 1874, demolished 1923; was built of blocks of Asbestine, as asbestos-like material. (Not the same as asbestos shingles.) Are there any other Asbestine houses still in existence? This house is now almost totally forgotten. Couldn’t find a picture of the Rand House on the internet, so I uploaded this photo from my own collection:

LikeLiked by 1 person

I have never heard of asbestine block before! And that is a fascinating house. I’ll bet the insulation from hot or cold weather temperatures was fantastic.

That era between 1875 and 1925 is a fascinating one in housing (or really almost any kind of architecture). In my city, the gorgeous old homes built before 1890 had become unwanted relics by the mid 1920’s, with the rich owners moving north and building new homes that have been better appreciated by later generations. The old Second Empire and similar homes had been cut into apartments by the 20’s and relatively few of them have survived in anything close to their original splendor. Perhaps the Great Depression slowed the cycle of obsolescence in housing enough to where the grand homes of the 10’s and 20’s remained desirable longer and did a better job of stabilizing the neighborhoods.

LikeLike

The house in Photo #5 looks like a J. H. Daverman design No. 124, the same architectural firm which designed my house (Mine is a No. 58).

LikeLiked by 1 person

I have always wondered if Sears commissioned designs from well-known architects or if they had guys who were good at copying the latest styles and pulling them together for a cohesive design to sell as a kit.

LikeLike

I’ve never seen it anywhere, but haha! to the last paragraph!

LikeLiked by 1 person

It’s a sickness. 🙂

LikeLike

JP – Very clever with the last paragraph! I am amazed just how versatile Sears, Roebuck & Co. really was in its time. I see vintage ads from time to time that featured the build-it-yourself homes by Sears et al. It looks like they had their hands in many pots, but luckily not palm down in the cement! We have a Sears in our City. It was the anchor store in an outdoor mall, but closed a few years ago. It was such a thriving store and the parking lot was filled, no matter when you drove by. It will be demolished to put a hotel and several businesses in its stead. You will be counseling the young’uns on home ownership as time goes on – they are lucky you are Dad and not billing them at your hourly rate. 🙂

LikeLiked by 1 person

Sears is indeed a sad story about a slo-mo train wreck. They didn’t know at the time that they were the analog version of Amazon. And not even Amazon will sell you a house kit. At least I don’t think so.

Yes, the kids would not have been able to afford me. 🙂

LikeLiked by 1 person

Yes, it’s a shame. Sears’ vintage ads for homes were way ahead of their time as were the devices you featured. Good thing your moniker is “Dad” not “Esquire” then. 🙂

LikeLiked by 1 person

Fascinating story. I didn’t realize concrete blocks had such a long history.

LikeLiked by 1 person

Isn’t amazing what kinds of stories curious people who write can pull out of the most ordinary things. But I will admit, getting one of of concrete blocks was not an obvious choice.

LikeLiked by 1 person

With the initial photo I thought, “Nope, never seen that look before”. Then you included the Victorian house after the Sears ad and I thought, “Wait, I’ve seen that look EVERYWHERE.” The Palmer machine video was worth the watch (interesting choice of soundtrack) because there’s more work and crafting involved than I expected. You should get one (eBay?) and make “writer’s blocks” for your grandchildren. See? Your effort in the final paragraph was not lost on me 🙂

LikeLiked by 1 person

Saturday, I tried the math from the Sears Wizard machine – the video was about right because the ad worked out to a block every 4 minutes through an 8-hour day. That would be a really, really long day. All I kept thinking about as I watched the video was “Ferkryinoutloud, get a bigger scoop!”

And your idea about making Writer’s Blocks is pure gold!!

LikeLike

I was 60 years old before I figured out the difference between cement and concrete. I learn more on your Blog than I did in school.

LikeLiked by 1 person

I don’t think you are alone in that. I grew up hearing my mother refer to “cement” as the stuff that driveways and porches were made of. At least you were probably not raised to say CEE-ment (like the Beverly Hillbillies and their swimming pool they called the “CEE-ment pond”)

LikeLike

I definitely should have been doing my homework instead of watching the Beverly Hillbillies. I always thought they were our neighbors because we lived on Beverly Road downhill from the rich houses.

LikeLiked by 1 person

Where would be a good place to find an old machine or a newer version?

LikeLiked by 1 person

Wow, I have no idea! I think there are some sources online that sell modern replicas of the blocks, but I don’t know about the machines.

LikeLike